MSD700 No.1005 – Rental Rover Guidebook

⚠️ Safety Precautions

Remote Operation Safety

This device can be operated remotely. Always ensure that the surrounding area is clear of people and objects before operating. Use brakes properly.

No Riding Policy

Do not ride on top of the device. This may cause tipping or accidents.

Load Capacity

When attaching additional equipment, do so within the load capacity. Use bolts and securely fasten them.

Crawler Maintenance

When reattaching a derailed crawler, be very careful to avoid hands getting caught in rollers or crawlers.

Battery Management

The device is powered by an internal battery. If voltage drops below the specified level, recharge immediately. Continued use under low voltage can cause battery damage requiring replacement.

Surface Restrictions

Do not operate on frozen surfaces. Operation on public roads is prohibited.

🛠️ Technical Specifications

Hardware

🔧 Main Components

Battery System

2 units (connected in parallel)

Drive Motors

2 units

Rubber Crawler

2 units

Control System

Advanced microcontroller

📋 General Specifications

Basic Information

- Model Name: Micro Construction Machine

- Weight: Approx. 150 kg

- Drive System: Electrically powered crawler type

- Power Supply: Lithium-ion battery (DC 24V)

Performance

- Speed: 1.8 km/h

- Climbing Capability: 15° (25° tilting tolerance)

- Communication Range: Up to 200 m (line of sight)

- Environmental Protection: Approx. IP54

Power & Charging

- Operating Voltage: 29.7 V ~ 21.0 V

- Charger: Dedicated charger (AC 100V)

🔍 Detailed Equipment Specifications

Battery System

Motor System

Rubber Crawler

Control Unit

Software

💻 Source Code Repository

Arduino Source Code

Description: Complete Arduino source code for MSD700 No.1005 control system including motor control, sensor integration, and communication protocols.

Wiring Diagram

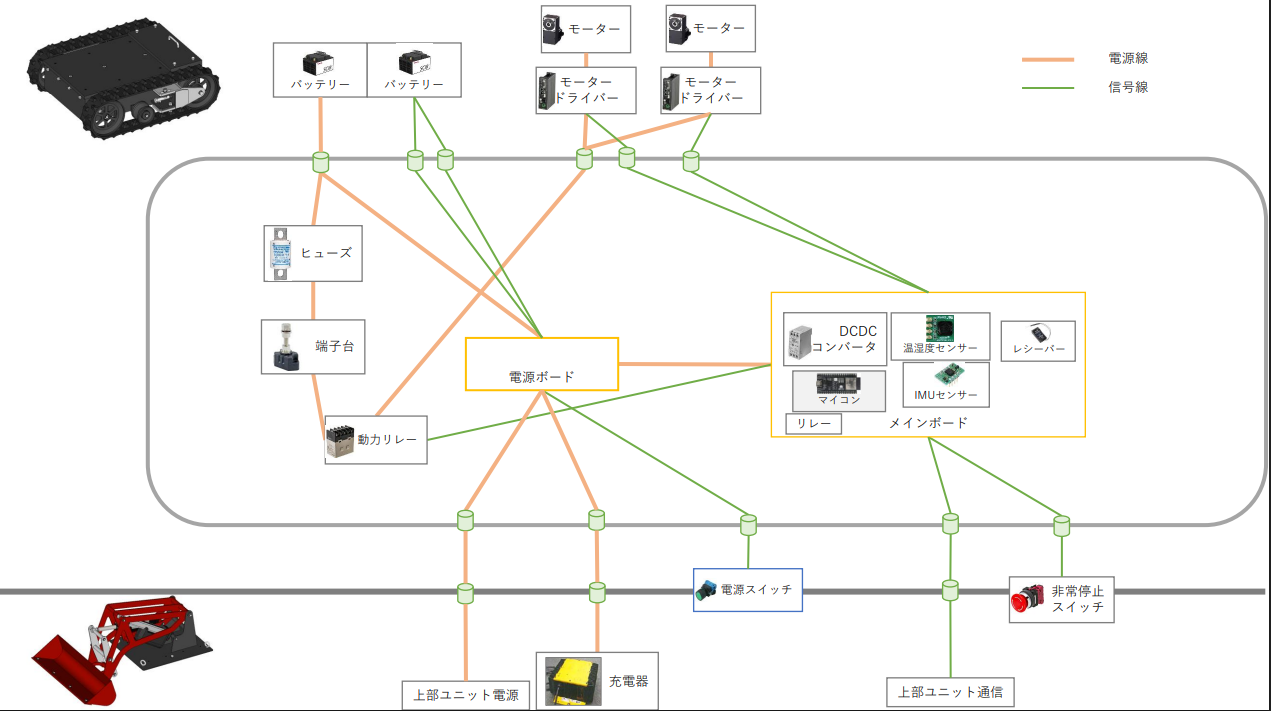

🔌 Complete System Architecture

Overview of the entire electrical system including power distribution, control units, and sensor connections

Complete System Architecture

Comprehensive electrical system layout showing power distribution, control units, and interconnections

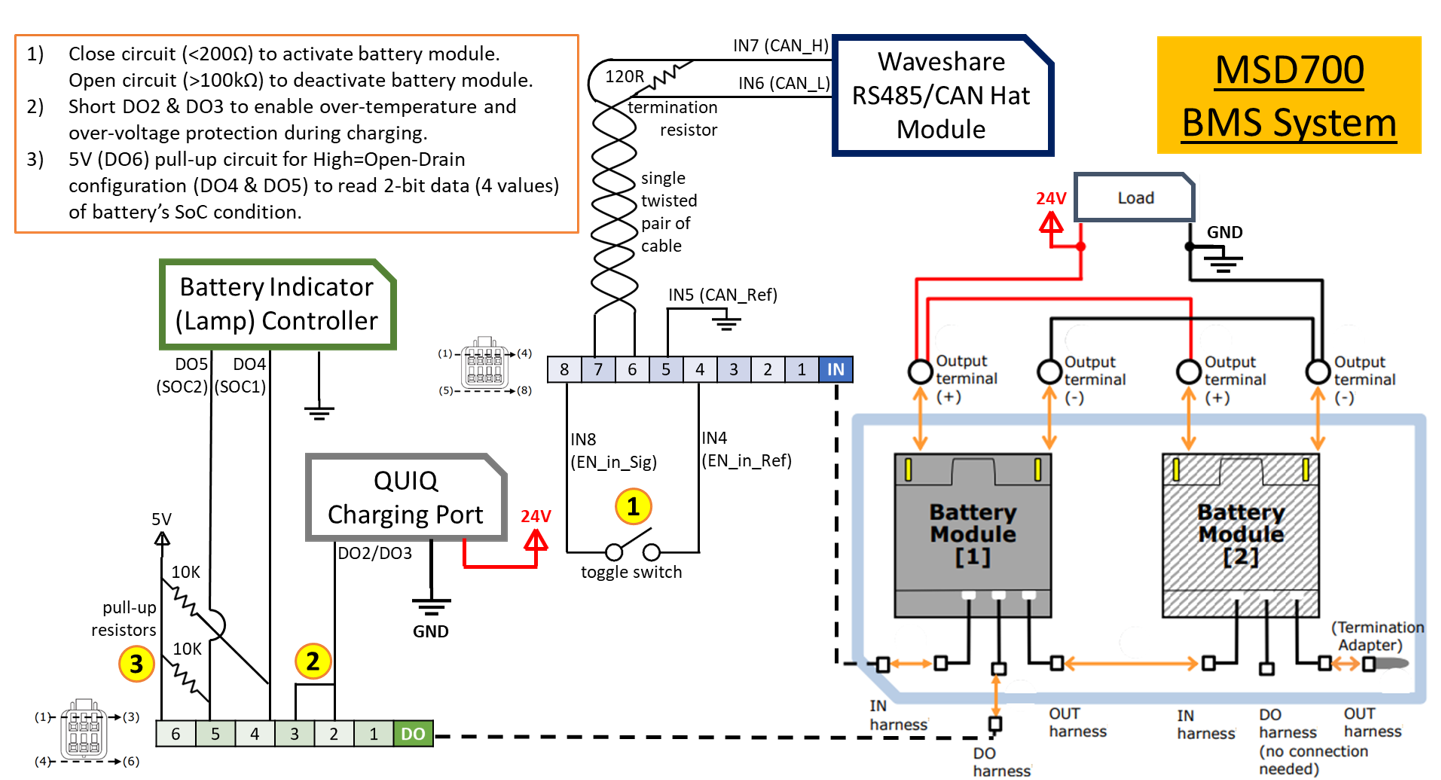

🔋 Battery Connection Details

Detailed battery wiring configuration and parallel connection setup

Battery Parallel Connection Setup

Detailed wiring schematic for parallel battery configuration

Battery Unit 1

Parallel Configuration

Battery Unit 2

⚠️ Battery Safety Guidelines

- Ensure proper polarity when connecting batteries

- Use appropriate gauge wire for current capacity

- Install fuses on positive terminals

- Monitor battery temperature during operation

- Follow manufacturer's charging procedures

🔧 Physical Wiring Implementation

Step-by-step wiring process and connector details for field installation

📸 Actual Installation Photos

Power Distribution Setup

- Connect battery positive terminals together

- Connect battery negative terminals together

- Install main power switch on positive line

- Add fuse protection (30A recommended)

Controller Connections

- Connect main power to controller input

- Wire control signals to motor drivers

- Establish communication lines

- Connect emergency stop circuit

Motor Driver Wiring

- Connect motor driver power inputs

- Wire three-phase outputs to motors

- Connect encoder feedback signals

- Install thermal protection

📋 Connector Specifications

PCB Circuit Diagram

🔧 Unified PCB Design

Shared circuit board design for MSD700 models 1005, 1006, and 1007 ensuring consistency and cost-effective manufacturing.

📄 PCB Circuit Diagram Document

Complete circuit schematic and board layout for MSD700 Bucket Model PCB

📊 PCB Technical Specifications

📐 Physical Dimensions

⚡ Electrical Specifications

🌡️ Environmental Ratings

🔧 Manufacturing Standards

🔧 Component Layout & Placement

Power Management Zone

Microcontroller Zone

Motor Driver Zone

Communication Zone

🏭 Manufacturing & Assembly Notes

Production Guidelines

- ✓ Automated SMT assembly recommended

- ✓ Reflow profile: Lead-free SAC305

- ✓ AOI (Automated Optical Inspection) required

- ✓ In-circuit testing (ICT) for all power rails

- ✓ Conformal coating for outdoor use

- ✓ Final functional testing mandatory

Assembly Sequence

- Step 1: SMT component placement

- Step 2: Reflow soldering

- Step 3: Through-hole components

- Step 4: Wave soldering

- Step 5: Cleaning & inspection

- Step 6: Programming & testing

- Step 7: Final quality check

Critical Notes

📋 Revision History

🎮 Operation Methods

Power On Procedure

Open the Main Body Cover

Carefully open the main body cover to access the internal components and power controls.

Main body cover opening procedure

Main body cover opening procedure

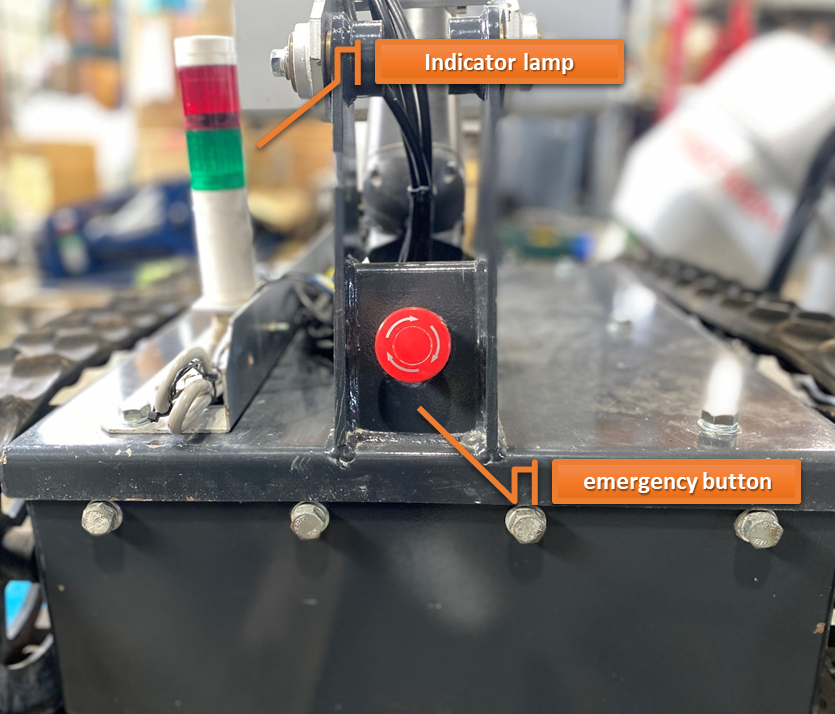

Press Main Power Switch

Press the main power switch and confirm that the power indicator lamp lights up green, indicating successful power activation.

Power switch activation and green indicator confirmation

Power switch activation and green indicator confirmation

Release Emergency Stop Button

Release the emergency stop button to complete the power-on sequence and enable full system operation.

Control Methods

Futaba Radio Controller

This MSD700 is controlled using a Futaba radio controller for precise remote operation.

Futaba radio controller with joystick and switch layout

Futaba radio controller with joystick and switch layout

Turn On Controller

Turn on the controller by switching the power switch to ON position.

Activate Motor & Arm Power

Flip Switch A downward to enable motor and arm power.

Motor Control

Use the left joystick to control the motor movement and navigation.

Arm Control

Use the right joystick to control the robotic arm operations.

Shutdown Procedure

Safe System Shutdown

Follow these steps carefully to ensure safe shutdown of the MSD700 system.

Press Emergency Stop Switch

Immediately press the emergency stop switch to halt all system operations safely.

Raise Switch A

Move Switch A to the upward position to disable motor and arm power.

Turn Off Controller Power

Switch the controller power to OFF position after ensuring Switch A is in the up position.

Main Power Switch OFF

Open the main body cover and switch the main power switch to OFF position.

Safety Reminders

- Always press emergency stop first

- Ensure Switch A is raised before powering off controller

- Wait for all moving parts to stop completely

- Confirm all indicators are off before closing covers

⚡ Charging Procedure

Precautions

Important Safety Precautions

Please read and follow these safety precautions carefully before charging the MSD700 system to ensure safe operation and prevent accidents.

Electrical Safety

Avoid touching metal pins on the charging plug or connector to prevent electric shock.

Cleanliness & Dryness

Ensure the charger, connectors, and cables are clean and dry before use.

Designated Equipment Only

Use only the designated charger and charging connector supplied with the unit.

Voltage Verification

Confirm that the AC outlet voltage matches the specified rating (AC 100 V).

Dry Hands Required

Do not operate the charger or main unit with wet hands.

Fire Prevention

Keep flammable materials away from the charging area.

Cable Protection

Do not place heavy objects on charging cables to prevent damage.

Emergency Contact

If you notice any abnormal conditions during charging (sparking, unusual heat, strange odors), immediately disconnect the power and contact technical support.

Battery Connection

MSD700 Charging Procedure

Follow these steps carefully to properly charge the MSD700 system using the designated charger and connections.

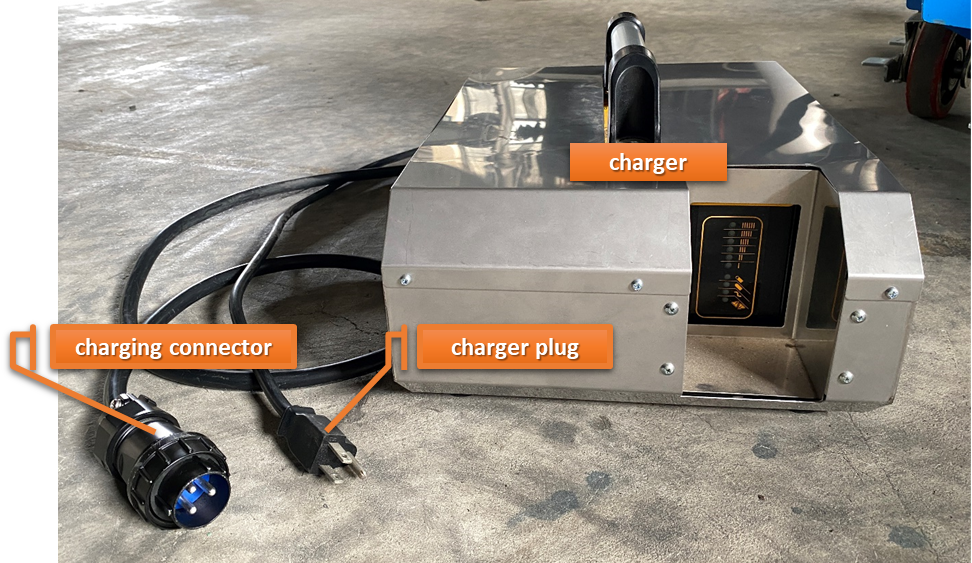

[Charger] Attach Charging Connector

If not already connected, attach the charging connector and charger plug to the charger.

Attach charging connector to charger

Attach charging connector to charger

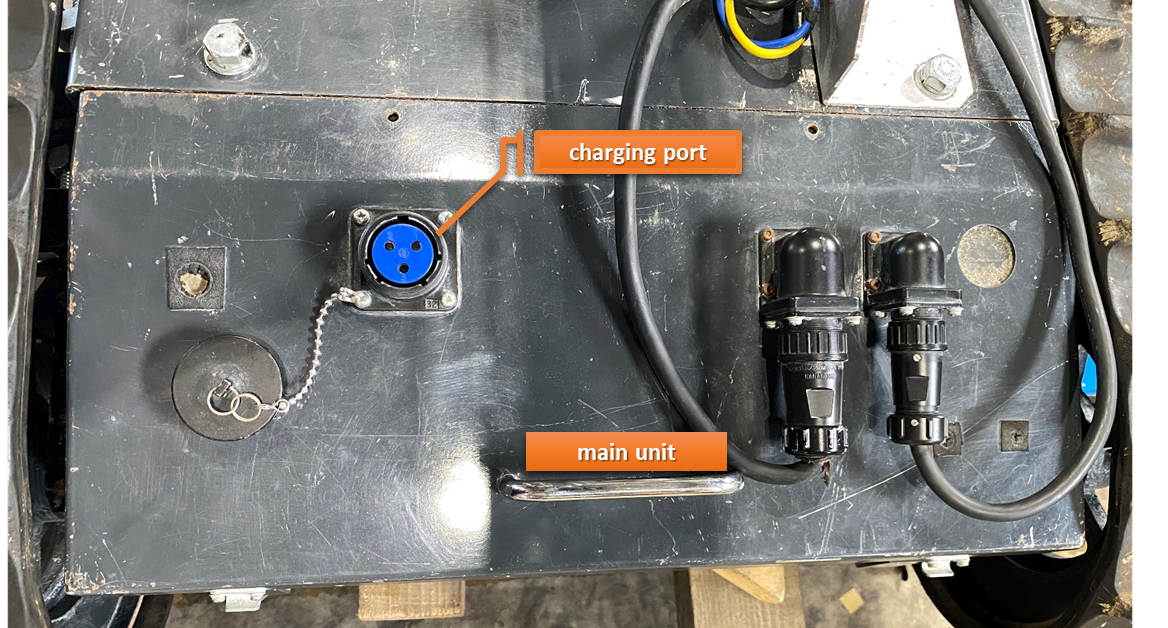

[Main Unit] Connect to Charging Port

Connect the charging connector to the main unit's charging port securely.

Connect to main unit charging port

Connect to main unit charging port

[Main Unit] Switch ON Internal Power

Switch ON the internal power switch of the main unit to enable charging mode.

Activate internal power switch

Activate internal power switch

[Charger] Plug into AC 100V Outlet

Plug the charger into an AC 100 V outlet. Ensure voltage compatibility before connection.

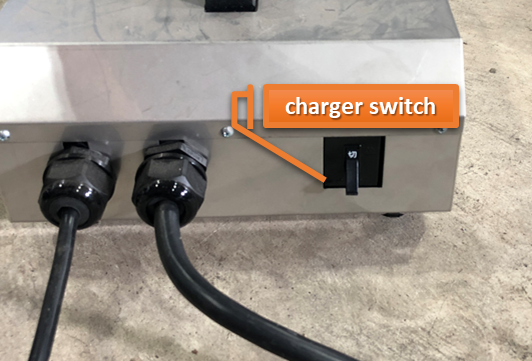

[Charger] Turn ON Charger Switch

Turn ON the charger switch to begin the charging process.

Turn ON charger switch

Turn ON charger switch

✅ Charging Active

Charging will begin — check the charger indicator lights to confirm proper operation.

Indicator Lights

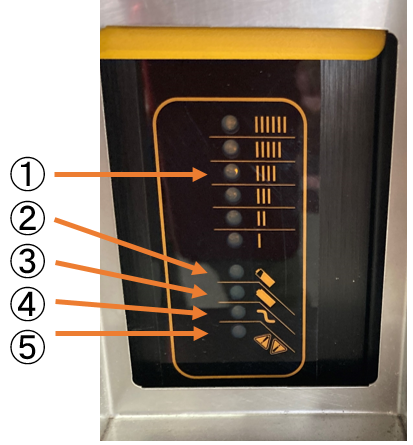

Charger Status Indicators

Monitor these indicator lights on the charger to understand the charging status and ensure safe operation of the MSD700 system.

Charger indicator lights panel

Charger indicator lights panel

【Ammeter (Orange)】

【Bulk Charging Indicator (Orange)】

【Charge Complete Indicator (Green)】

【AC Indicator (Orange)】

【Error Indicator (Red)】

Charging Behavior & LED Sequences

When AC Power is Applied

Typical LED Indications

Charging Started

Battery Charged Over 80%

Charging Complete

Note:

Charging will not automatically restart.

To recharge, turn off the charger, wait 30 seconds, then turn it back on.

🔧 Abnormalities and Countermeasures

If the error indicator (⑤) blinks, refer to the table below to identify the issue and apply the appropriate countermeasure. The number of blinks indicates the specific type of error.

| Number of LED Blinks | Abnormality | Charging Forced Stop | Detection Threshold | Countermeasure |

|---|---|---|---|---|

|

1

blink

|

Battery voltage too high

|

Recovers after avoidance

|

Voltage above 28.6 V

|

Charging automatically resumes when battery voltage returns to normal operating range

|

|

2

blinks

|

Battery voltage too low

|

Recovers after avoidance

|

Voltage below 16.5 V

|

Charging automatically resumes when battery voltage returns to normal operating range

|

|

3

blinks

|

Charging time exceeded

|

Forced stop

|

CC mode: over 2.5 hours

CV mode: over 0.5 hours

|

Unplug AC power, wait 30 seconds, then reconnect AC power to restart charging

|

|

4

blinks

|

None

|

—

|

—

|

—

|

|

5

blinks

|

Charger temperature too high

|

Forced stop

|

Output turns off at internal temp 83°C

|

Charging restarts when temperature drops, but error clears only after unplugging AC power for 30 seconds and reconnecting

|

|

6

blinks

|

Charger internal fault / DC wiring connection failure

|

Forced stop

|

- Charger internal fuse blown

- Battery wiring loose

- Other internal faults or failures detected

|

Check DC wiring, unplug AC power for 30 seconds and reconnect; if error persists, contact dealer

|

📕 Description

Document Information

MSD700 Technical Documentation

Contact Information

Technical Support & Documentation